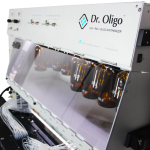

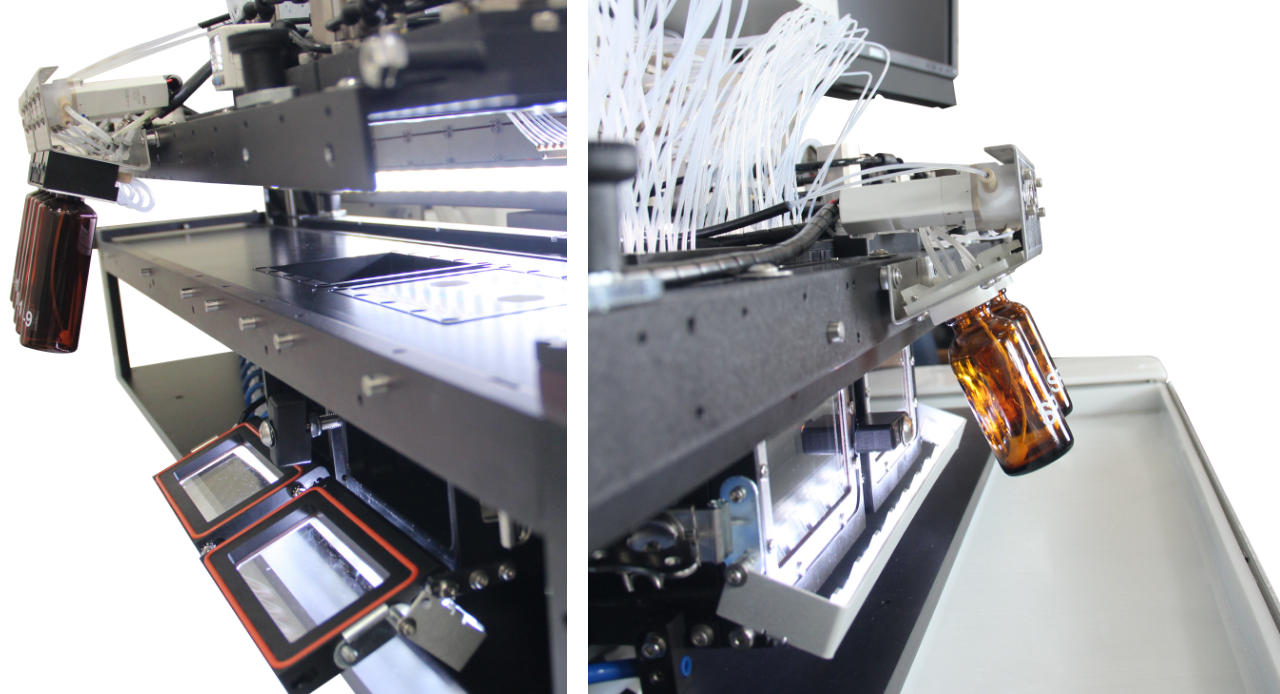

The new Dr. Oligo 192XLc can be operated in both R&D and high-throughput production facilities, with the ability to utilize synthesis plates or individual columns, making it the most versatile high-throughput DNA/RNA oligo synthesizer yet. Synthesize with up to 37 Reagents, Up to 5 umol Scale.

Overview of the Dr. Oligo 192XLc Features:

- Synthesize 1 to 192 oligos in a run, with up to 37 total reagents (27 specials and 10 standards) and up to 5 umol scale per column, with your choice of synthesis plates or columns

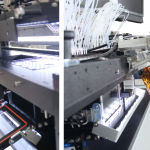

- Extremely efficient mixing or recycling of any reagent dispensed into each well using our patent pending in situ mixing system

- The entire volume of reagent delivered to each reaction well is thoroughly mixed with the synthesis media resulting in optimal use of all reagent delivered

- Minimize the volume of each reagent needed to achieve near 100% reaction efficiency

- Custom Biolytic valves provide faster, more consistent response times and fill with less volume thus reducing waste

- Newly designed dispense nozzles maintain desired delivery volumes and minimize the chances of reagents dripping or drying out

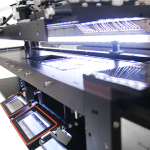

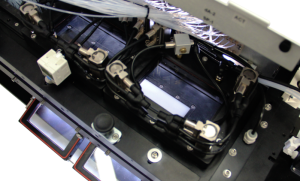

- Individual plate-sized synthesis chambers result in more precise pressurization and control of reagents flowing through reaction wells

- Smaller synthesis chambers (one for each 96-well plate or columns) reduce gas consumption

- Dispense 8 or more nozzles simultaneously with an accuracy down to 2 ul [1]

- Automatic nozzle washing at the end of a synthesis if desired

- High speed closed loop motion system.

- On demand Auto Reprime of Amidite Nozzles

More reagents create more opportunities to push your experiments to the next level. The Dr. Oligo 192XLc is equipped with the most reagents we have ever put in a high throughput oligo synthesizer. Synthesize anywhere from 1 to 192 oligos using up to 37 total reagents and up to a 5 umol scale.

Up to

max synthesis scale

Synthesizes

in one run

Max up to

27 specials and 10 standards

The Dr. Oligo 192XLc allows you to control the flow rate, providing more precise, fast, and accurate reagent flow delivery to every well. The Dr. Oligo 192XLc is designed with our novel patent pending mixing system, resulting in the highest possible chemical reaction efficiency using minimum reagents. It delivers the volume of each reagent needed to obtain the optimal molar excess for achieving the highest reaction efficiency.

A new implementation of the draining system empties the columns more efficiently.

This system overcomes chemistry over-consumption and reaction inconsistencies that are a result of well-to-well flow rate variability and other issues typical in high-throughput synthesis media.

The Dr. Oligo 192XLc allows for many unique configurations to meet the requirements of R&D and production facilities. Dedicated special amidite positions mounted on the nozzle plate reduces waste of expensive reagents by using shorter tubing, allowing an easier and shorter delivery to every well.

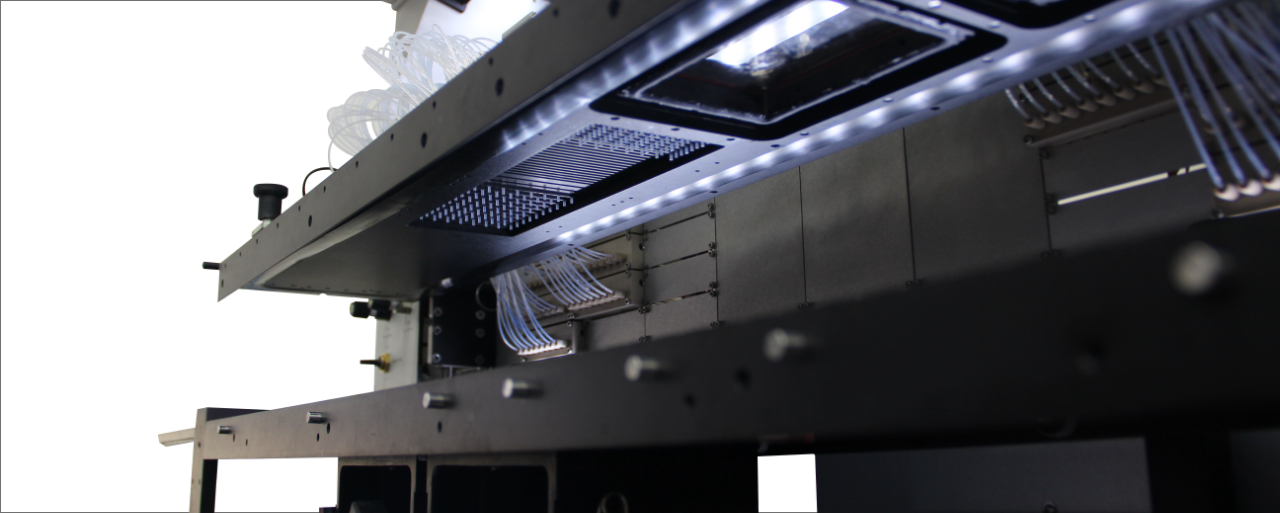

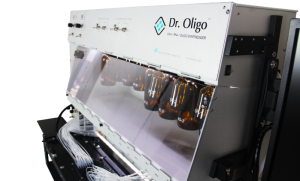

All of our Dr. Oligo XLc models are designed to maximize your safety while optimizing user efficiency. The Dr. Oligo 192XLc is designed with a safety window, guard rails, and LED backlighting. The purge, drain, pneumatic and bottle plumbing are separated allowing for easier access to each system resulting in simpler maintenance and troubleshooting.

The synthesis and waste chamber windows allows you to observe both top and bottom of the reactions plates at the same time.

Chemically resistant LED lights allows for better observation of reagent flows through the synthesis medium and reagent bottle content.

The saftey window may protect against splash and unexpected events.

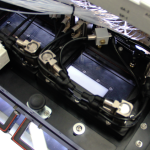

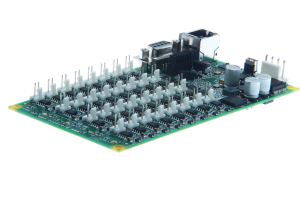

Real-time Valve Monitoring

Prior to and during synthesis, the control boards monitor the electrical integrity of all instrument valves. If any valve is in poor condition, the run will immediately pause and allow an operator to resolve the issue.

Shockproof Design

Enables precise dispensing of reagents and monitoring of inputs while the instrument is in operation.

On-board Timing

Guarantees reliability by executing the exact timing required for delivery.

Antistatic Design

Ensures boards are not affected by static electricity that can build up and disrupt delivery.

Valve Short Protection

If a valve shorts electrically, the board shuts down that valveʻs driver and protects itself, thus eliminating the need to replace a board.

All of our Dr. Oligo Synthesizers are equipped with our Biolytic Board. The custom Biolytic control board is designed specifically to ensure proper reagent dispensing of as little as 2 ul.

The Biolytic Control boards consist of 32 outputs and 8 inputs, and includes a shockproof and antistatic design, on-board timing, valve short protection, and real-time monitoring of the valves’ electrical integrity.

Security and Encryption

Encrypted communication increases system uptime and improves the overall quality of each synthesis.

Hardware Monitoring

The New monitoring system works in conjunction with our control boards to prompt users to act in the event of hardware failure.

The Dr. Oligo 192XLc runs using Biolyticʻs powerful instrument control software. The software provides critical information on the conditions of the instrument and offers customization for coupling and oxidizer.

Backed by Biolytic Lab Performance, Inc.ʻs 25 years of experience in reliable and efficient Oligo Synthesizers, customers all over the world use nucleic acids produced by our Dr. Oligo synthesizers for their unique purposes. From applications like gene synthesis, genetic diagnostic test kits, PCR/RT-PCR, siRNA/RNAi, miRNA, CRISPR Cas9 and DNA/RNA sequencing – to broader areas like evolutionary history, forensics, immunotherapy, diagnostic and therapeutic research – to high-throughput screening, modified oligos, mixed backbones, LNAs and the visual detection of virus RNA such as COVID-19 following RT-LAMP amplification with DNA primers – the variety is tremendous. The Dr. Oligo line has evolved along with cutting-edge discoveries, and the 192XLc will continue to play a significant role in modern science.

At Biolytic, customer experience and needs are at the center of every innovation and new development. The Dr. Oligo 192XLc comes with an 1-year manufacturer warranty in North America. Warranties in all other regions may vary so please check with your sales representative for details. During your post-warranty period, you may choose from our professional full service, preventative maintenance, and low-use plans. Most plans are available with on-site service (when possible) and/or remote technical support.

As with all our instruments, Biolytic Certified Instrument Training (CIT) is available for the Dr. Oligo 192XLc. Upon successful completion of the certificate program, recipients will be able to understand the function of the instrument, how to operate, and perform basic troubleshooting. The training, coupled with the Dr. Oligo 192XLcʻs simple maintenance, will decrease total operation costs. Please contact our sales department for more information on this optional program.

Our Biolytic Team is constantly developing new synthesis capabilities to improve our products and services. We strive to provide our customers with all the features and functionality they need. We love ❤ feedback. If you would like to participate in sending us feedback on any of our products, please send us an email or find us on social media.

Building on 25+ years of expertise, Biolytic Lab Performance Inc. develops reliable and efficient oligo synthesizers; our instruments are strategically constructed to optimize high quality and cost-efficiency. We are committed to providing great products, and helpful end-to-end service for our customers.

[1] Actual minimal controlled dispense volume consists of the custom Biolytic dispense valves, Biolytic Board V1 and an appropriate reagent delivery system

[2] Unexpected events such as bottle breakage

OLIGOS SYNTHESIZED IN ONE RUN: 1 – 192

SYNTHESIS SCALES: 5 nmol to 5 umol

SYNTHESIS CAPABILITY: DNA, RNA, LNA, 2′-Modified RNA, Mixed Backbones DNA and RNA

FLOW CONTROL: Positive Pressure

SPECIAL AMIDITE DELIVERY SYSTEMS: Up to 27

STANDARD AMIDITE DELIVERY SYSTEMS: 10 (A, C, T, G, and 6 standard reagents)

DISPENSE NOZZLES PER REAGENT: 8

DIMENSIONS (W X D X H): 60 x 22.9 x 31.8 inches

DIMENSIONS WITH GUARD RAIL (W X D X H): 81.3 x 22.9 x 31.8 inches

GAS INPUTS: Bottle Blanketing and Purge/Drain and Pneumatics

PNEUMATICS: Requires 90-120 PSI

USER CONTROL: PC with latest Windows Operating System

MAXIMUM RELATIVE HUMIDITY: 60%

POWER: 100-240 VAC, 50-60 Hz, 1,000 VA

MADE IN THE U.S.A. Fremont, CA

CERTIFICATION: CE

- Easy Trityl Collection

- Auto Nozzle Cleaning during Synthesis

- Manual Mode Nozzle Cleaning

- Additional Wash Bottles Available

- Additional Deblock Bottles Available

- Additional single reagent Add-on-Available

- Map Amidites

- Powerful Protocol Editor

- Flexible Loading of Oligos onto Plate(s)

- Flexible Loading of Oligos onto system

- Intelligent Auto Reprime of Amidite Nozzles

- View Synthesis Information Any Time During Synthesis

- Start Synthesis Ahead from Any Point

- Vary Protocol Based on Cycle

- Base Character Driven Chemistry

- Superior Performance

- Zero Reverse Flow Contamination

- Custom Biolytic Valves

- Hardware Monitoring System

- Custom Biolytic Developed Software and Hardware

- Over 25 years of industry experience